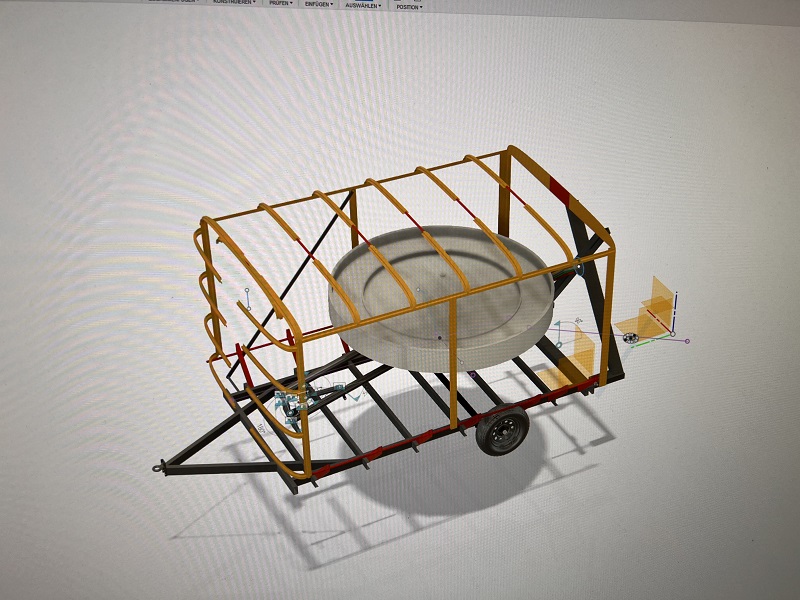

Test turbine on mobil platform

To confirm the theoretical prediction, an 8 feet diameter

turbine has been designed and build. It has a dome nozzle and exit diffusor which reduce

the turbine entry area to 1/2. 36 pitch adjustable turbine blades drive a 3 phase AC generator.

The foldable tower erects to two position and leanes 15deg forward into the windstream

to counteract tilt force.

First position is 7 feet high. In that position a second 3 blade turbine (with

same AC Generator type) operates paralell in same wind condition and give a direct

comparison to the test turbine performance. Based on estimates the energy out put

should be 3-4 times higher than the 3 bladed turbine.

The second position is 21feet high. In this position the blade pitch angle is manipulated

in order to find the "sweetspot" where pitch angle vs. turbine speed vs energy output

is most effective.