Energy Conversion

Kinetic energy 'Ekin': Every moving mass 'm' (body, liquid or gas) contains kinetic energy 'Ekin'. It is equal to half the mass of the body times the square of the velocity 'v'. For wind turbines, the moving mass is the air that flows through the rotor surface of the wind turbine.

Ekin=½∗m∗v2

Energy and Performance: The mass air flow through a turbine, also called mass flow ṁ, which flows through the rotor swept area of a wind turbine rotor (so-called rotor plane) in a specific time can be calculated by multiplying the rotor area, air density and wind speed.

ṁ=A∗ρ∗v

The power P is equal to the energy E per unit time. Thus results for the power of the wind.

PWind=E=½∗ṁ∗v2

Since the air through the rotor plane is proportional and the energy of the wind is dependent on the square of the wind speed, the power of the wind is dependent on the third power of the speed.

PWind=½∗ρ∗Π∗R2∗v3

Hence Wind speed the determining factor in the performance of the turbine. If the wind speed triples,

the power increases by 3x3x3 = 27 times.

Air density has a linear impact on performance. Cold air is denser than warm air,

so a wind turbine delivers about 11% more power at the same wind speed, e.g. at -10°C than at +20°C. Since the density of the air also depends on the ambient pressure, high and low pressure areas as well

as the altitude of the location have an impact on the performance and yield of a wind turbine.

Section Summary

The presented information applies for most current wind turbine typs. It does seem odd to

change the turbine entry wind speed as it appears to need extra energy to accelerate the mass air flow.

Betz Law (Check out detail at Wikipedia)

states that max. 59.3% (16/27) of the kinetic energy in the rotor plane windstream area can be

extracted independent of the wind turbine design. From this 59.3% the best performance turbines

can extract about 75-80% of the Betz limit 59.3%, hence only about 45% (59.3 * 3/4) of mass air flow

could be converted to electric energy.

In respect to "Betz" Wikipedia Qte:

"The Betz limit is based on an open-disk actuator. If a diffuser is used to

collect additional wind flow and direct it through the turbine, more energy can be

extracted, but the limit still applies to the cross-section of the entire structure. Unqte". It seems

that areodynamic enhancer do not change much the possible performance since the cross-section

is always the rotor swept area.

But is it? The presented concept here changes the "open-disk actuator" in a nozzle-diffuser actuator where the

windspeed is accelerated by constriction of the airflow. The cross-section reduces and

affects the "A" in the formula ṁ=A∗ρ∗v BUT the wind speed increases the "v" in PWind=½∗ρ∗Π∗R2∗v3

by the power of 3!

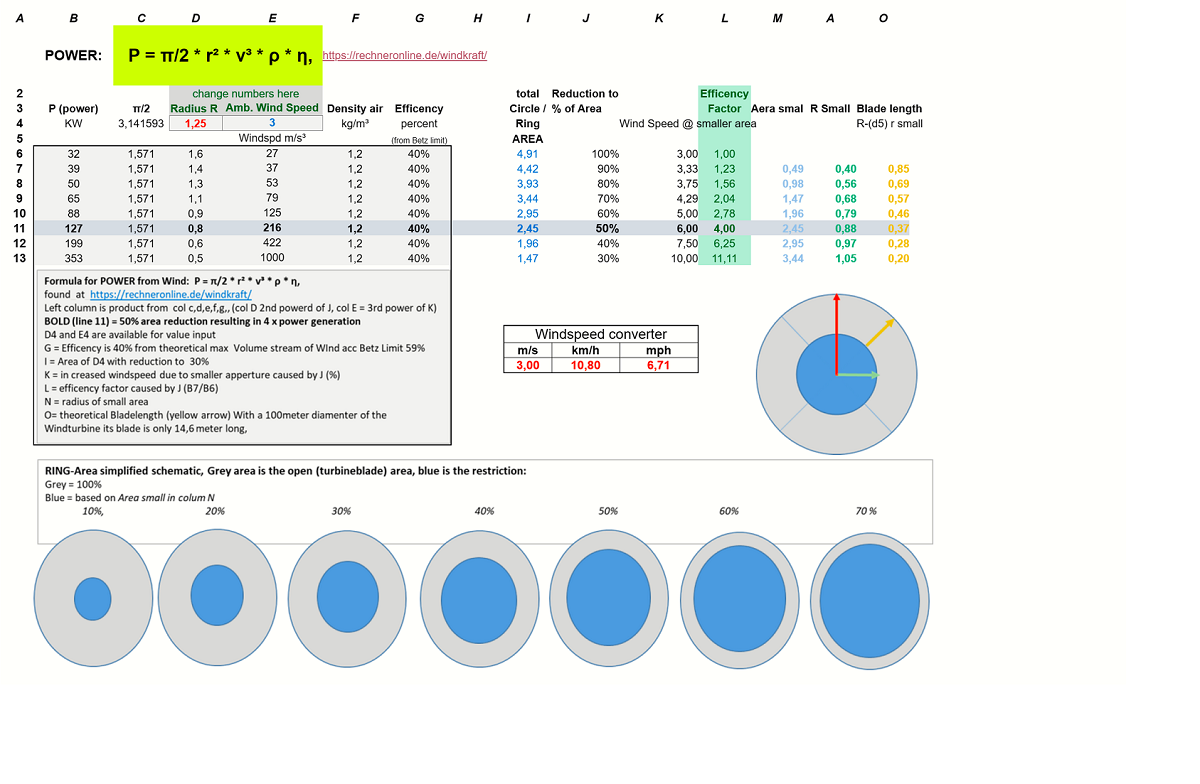

The following section visualizes relation of area vs. diameter vs. speed.

Entry section reduction

In the left table, the mass flow of the air is being calculated using the above

formulas and applying the law of conservation of mass for incompressible fluids, AEntry∗vEntry = AExit∗vExit

Entrance area * entrance velocity = exit area * exit velocity.

If the entry-section is reduced by 10%, 20%, 30%...70% (not practical but for demonstarion purpose only)

the airspeed on turbine entry-section will increase, i.e. at 50% area reduction, the speed doubles from

3 m/s to 6 m/s (column K)

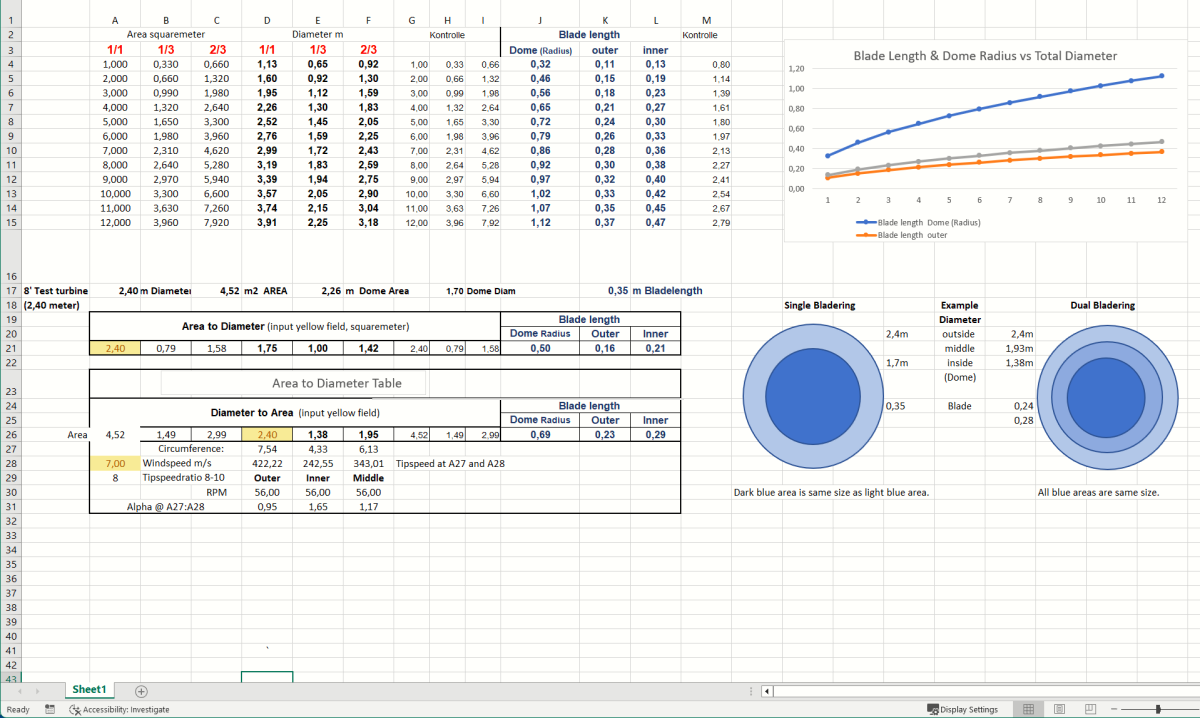

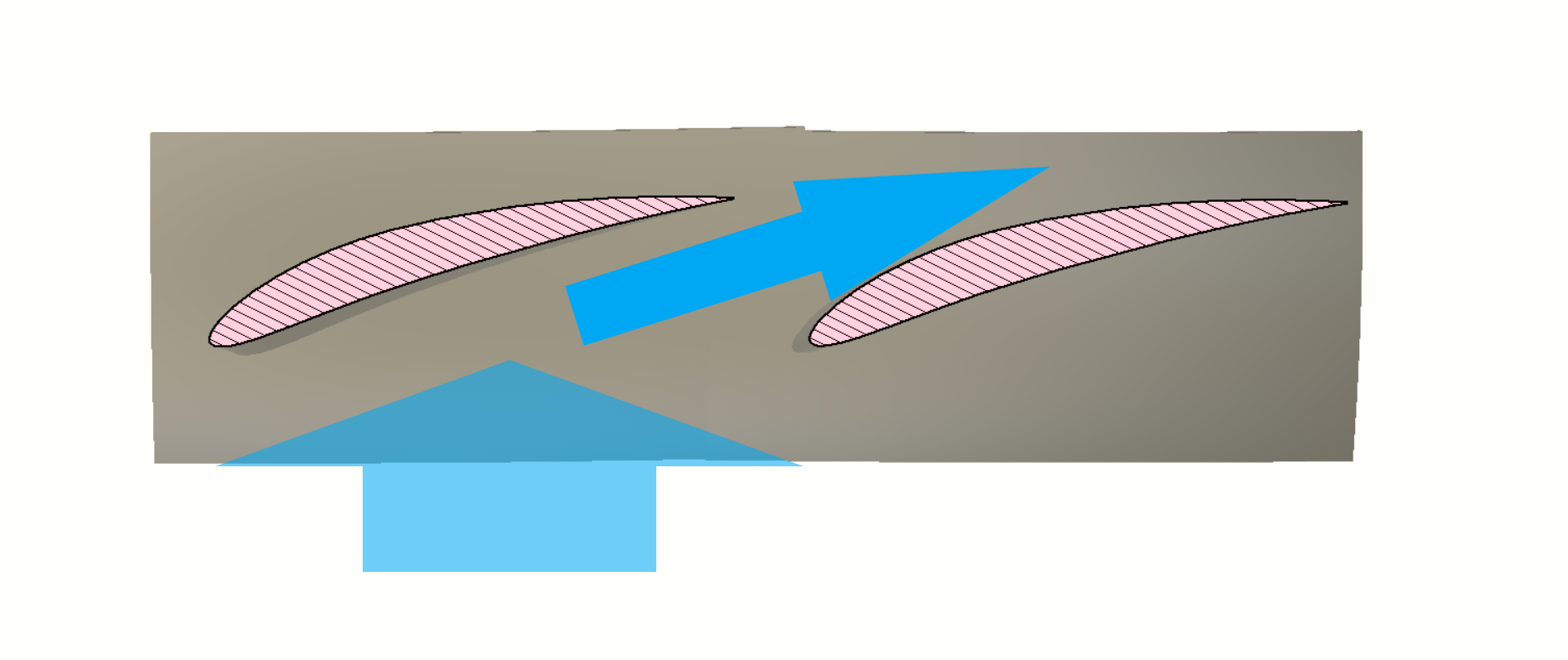

It also have to be considered, that the mass flow area reduces futher inside the the turbine blade "plane" area,

between blade leading- and it's trailing edge, see Sketch below.

The air pressure (density) does change a little through the turbine,

but to such a small extent that it is neglected in practical operation.

After the turbine blades, a diffuser is intended to enlarge

the "outlet opening" and guide the air flow out of the turbine without turbulence.

The second table demonstrate the dimension relations - Area flow vs ring area, Area vs blades etc.

Download the excel sheet to play with the different dimensions.

| Energy at Windturbine. |

Click Area vs Diam on new tab, to select "Area Windturbine |

Sketch: Mass flow acceleration through blade nozzle. |

|---|---|---|

|

|

|

Excell Table download and open in MS Excel or Google Sheets

Simulation

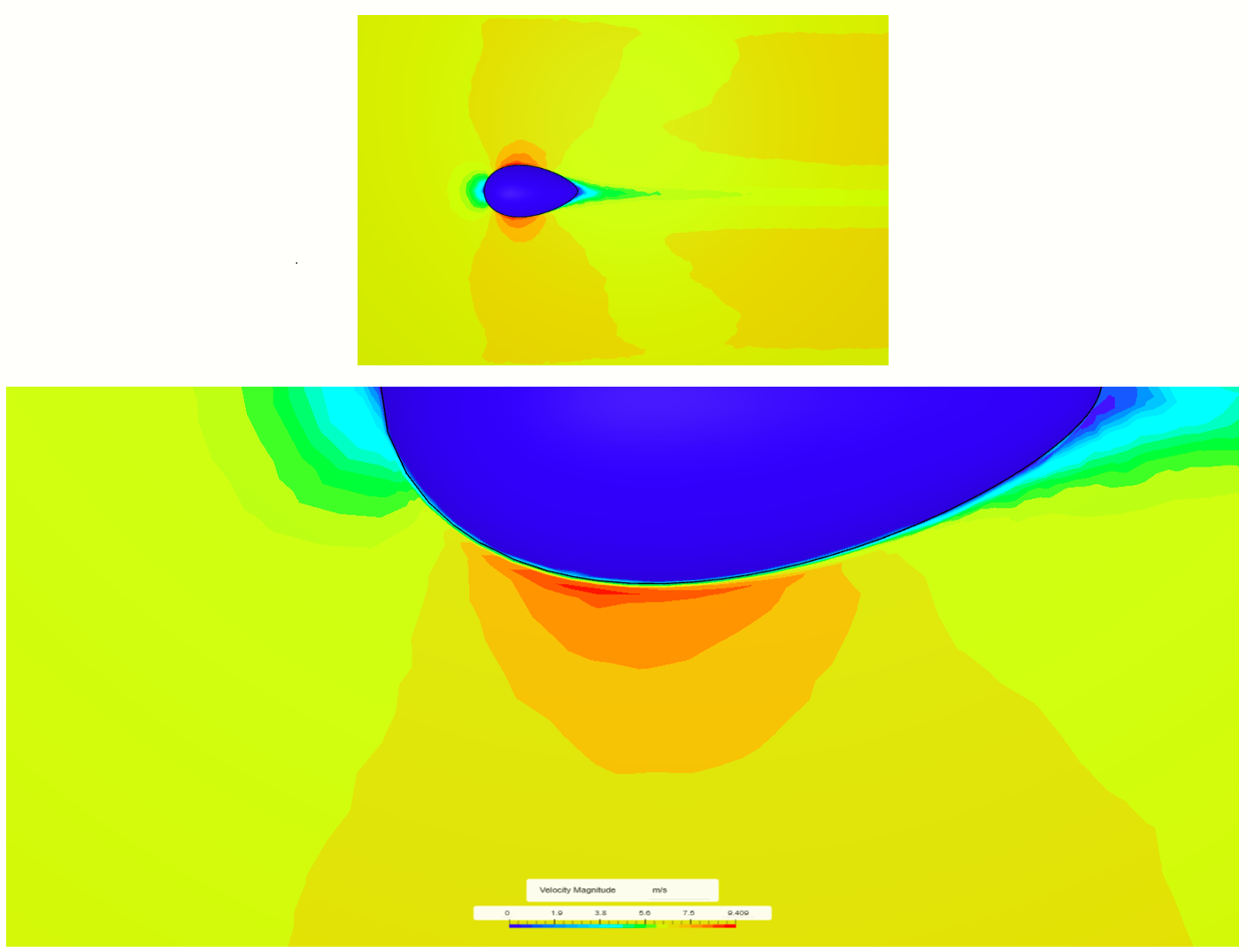

Various simulation have been run on SimScale website. They show that the principle areodynamic airflow follow the laws of Venturi and Bernulli. It shows also that it does not matter if the constriction in the airflow reduces introduce into a circular area shape or in a annulus area shape. Some of testruns are here:

Simulation program provided by